Why Understanding Shipping Container Sizes is Essential for Your Projects

Understanding shipping container sizes is crucial for effective project planning and execution. According to a recent report by the International Maritime Organization, container shipping accounts for about 90% of global trade. These containers come in various sizes, each suited for different types of cargo. Industry expert David Smith notes, "Choosing the right shipping container size can make or break logistics efficiency."

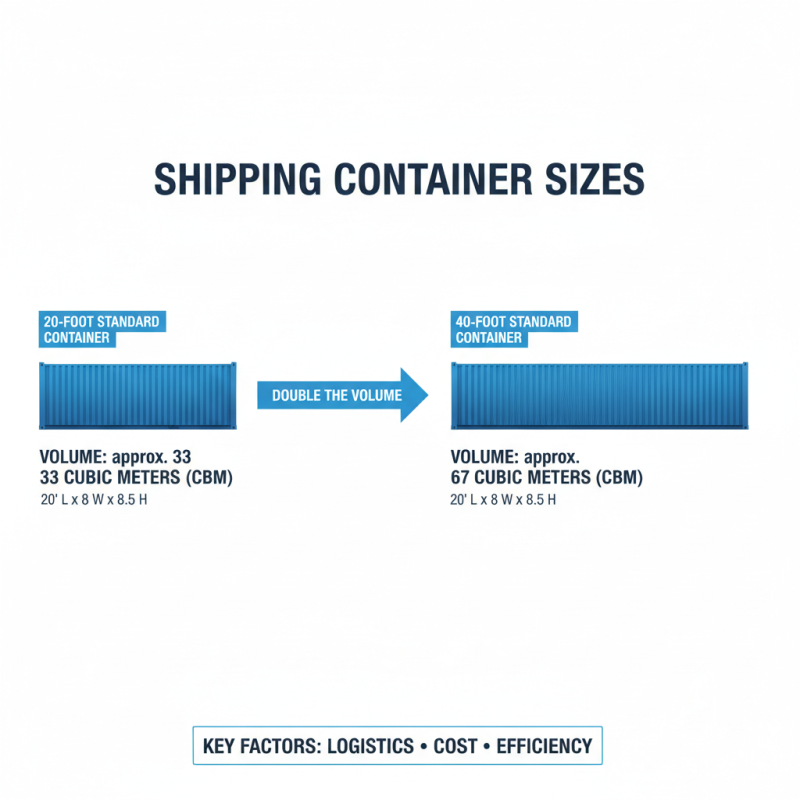

Obtaining the correct shipping container sizes enhances space utilization and cost efficiency. For example, a standard 20-foot container has a capacity of approximately 1,170 cubic feet. In contrast, a 40-foot container offers nearly double the volume. However, not all projects benefit from larger sizes. Sometimes, smaller containers reduce excess capacity and lower the risk of damage.

It's essential to evaluate your project's specific needs. Miscalculations can lead to delays and increased expenses. As the market evolves, staying informed about shipping container sizes has never been more important. Ignoring these aspects can result in missed opportunities. Thus, understanding the spectrum of available sizes is vital for anyone involved in the shipping industry.

Importance of Shipping Container Sizes in Project Planning

Understanding shipping container sizes is crucial for effective project planning. The right size can impact logistics, cost, and efficiency. The dimensions of standard shipping containers vary significantly. A 20-foot container has a volume of about 33 cubic meters, while a 40-foot container holds nearly double, at around 67 cubic meters. This difference can influence how materials are stored, handled, and transported.

According to industry reports, improper sizing of shipping containers can lead to a 10-15% increase in operational costs. For example, choosing a container that is too small might necessitate multiple trips. Each additional trip adds to fuel costs and time delays. On the other hand, using containers that are too large may result in wasted space. Empty volume inside containers equates to lost resources and inefficient use of capital.

Furthermore, the mismatch in size often complicates loading and unloading. A project may experience delays due to bottlenecks caused by improper container selection. It's evident that understanding the scale of your project is important. Every detail matters, and this includes choosing the right shipping container dimensions to optimize your project outcomes.

Common Shipping Container Dimensions and Their Applications

Understanding shipping container sizes is crucial for various projects. Containers come in different standard dimensions, like 20-foot and 40-foot units. A 20-foot container offers about 1,165 cubic feet of space. It's suitable for smaller moves or storage. In contrast, the 40-foot container provides roughly 2,390 cubic feet, making it ideal for larger shipments.

Also, consider the height of containers. Standard containers are usually 8.5 feet high. But high-cube containers are 9.5 feet tall. This extra foot can make a difference. It allows for more storage or larger items, which can be essential in design or construction projects.

Not every project requires a standard size. Custom container dimensions exist but are less common. This can create challenges for planning. It's important to weigh the pros and cons of using non-standard sizes. Ultimately, understanding container sizes can lead to better project outcomes and more efficient resource allocation.

Factors to Consider When Choosing Container Sizes for Your Project

When selecting shipping containers for your project, size matters significantly. Understanding the various container sizes can save you time and resources. Each project has unique requirements, from storage needs to transportation logistics.

Consider the volume of goods you need to transport or store. Are you moving large machinery or small items? A standard 20-foot container holds about 1,200 cubic feet. Meanwhile, a 40-foot container offers double that space. Choose wisely based on your inventory.

**Tip:** Always measure your cargo before deciding on a container size. Small discrepancies can lead to overloading, which is unsafe.

Don’t underestimate the weight limits of each container. A 20-foot container can carry a load of about 22,000 pounds. Failing to account for weight can result in extra charges or damage. It's also crucial to consider access points for loading and unloading. Will the container fit your project site?

**Tip:** Visit your site and assess the available space for a container. This can prevent unforeseen challenges later on.

Lastly, think about future needs. Projects can grow and change. Choosing a slightly larger container now could prevent complications later. A little extra foresight can avoid headaches down the road. Be smart about your choice.

Impact of Shipping Container Size on Transportation and Costs

Understanding the size of shipping containers is crucial. The dimensions directly impact transportation costs and logistics. A standard 20-foot container can hold up to 28,200 pounds of cargo, while a 40-foot container holds about 56,600 pounds. Selecting the right size can minimize shipping expenses. According to industry reports, shipping costs can increase by 30% if the wrong container size is chosen.

**Tip:** Always measure your cargo before deciding on a container size. This will help avoid unexpected costs during transportation.

The impact of container size on transportation is significant. Larger containers may seem more efficient, but they can lead to higher fees at ports. In contrast, smaller containers might require more trips. Balancing these factors is essential for project success. Poor planning can lead to delays. These delays can affect schedules and budgets.

**Tip:** Review multiple shipping options. Comparing various carriers can reveal cost-saving opportunities based on container sizes.

Shipping container sizes also relate to storage capabilities. Not having enough space can lead to wasted time and resources. Conversely, oversized containers can risk damage to cargo. It’s vital to find the right fit for your needs to ensure efficiency and effectiveness in your operations.

Impact of Shipping Container Size on Transportation Costs

This chart illustrates the average shipping costs associated with different container sizes, highlighting the importance of selecting the appropriate size for your project to manage expenses effectively.

Best Practices for Integrating Shipping Containers into Your Design/Layout

When integrating shipping containers into your design or layout, understanding their dimensions is vital. A standard 20-foot container measures 20 feet long, 8 feet wide, and 8.5 feet high. Meanwhile, a 40-foot container doubles that length but retains the same width and height. These measurements affect spatial planning, access routes, and overall aesthetics. According to a 2023 report by the Container Engineering Institute, improper sizing can lead to costly redesigns, wasting materials and time.

Incorporating containers requires creativity and practicality. Arranging multiple containers can create unique structures or spaces. However, efficiency matters. Research shows that nearly 45% of projects fail to consider local zoning laws regarding container usage. It's essential to understand how placement affects sight lines and functionality. For instance, a container placed too close to a building can obstruct views or inhibit airflow, leading to potential issues.

Proper insulation and interior design also play vital roles. Containers can be cold, making them uncomfortable without adequate treatment. The National Building Institute found that poorly insulated containers lead to a thermal efficiency loss of up to 35%. This statistic underscores the importance of integrating effective heating and cooling solutions in your plan. Balancing aesthetics with practical functionality requires careful thought. Every decision shapes the overall usability of the space, and a misstep can mean a redesign.

Shipping Container Sizes and Best Practices

| Container Type | Dimensions (ft) | Volume (CBM) | Weight Limit (kg) | Best Use Cases |

|---|---|---|---|---|

| Standard 20ft | 20 x 8 x 8.5 | 33.2 | 30,480 | Storage, Small Furniture, Equipment |

| Standard 40ft | 40 x 8 x 8.5 | 67.7 | 30,480 | Household Goods, Large Appliances |

| High Cube 40ft | 40 x 8 x 9.5 | 76.4 | 30,480 | Bulk Storage, High-Volume Retail |

| Open Top 20ft | 20 x 8 x 8.5 | 33.2 | 30,480 | Heavy Machinery, Bulk Loader |

| Reefer 40ft | 40 x 8 x 9.5 | 76.4 | 30,480 | Perishable Goods, Pharmaceuticals |

Related Posts

-

Why High Cube Shipping Containers Are the Best Choice for Your Storage Needs

-

Exploring the Versatility of 10ft Containers: Ideal Solutions for Your Space Needs

-

Why Second Hand Shipping Containers Are the Sustainable Choice for Your Business

-

Top 10 Essential Facts About Freight Containers You Need to Know

-

Everything You Need to Know About High Cube Shipping Containers

-

2025 Top 5 Uses for 20ft Shipping Containers You Need to Know